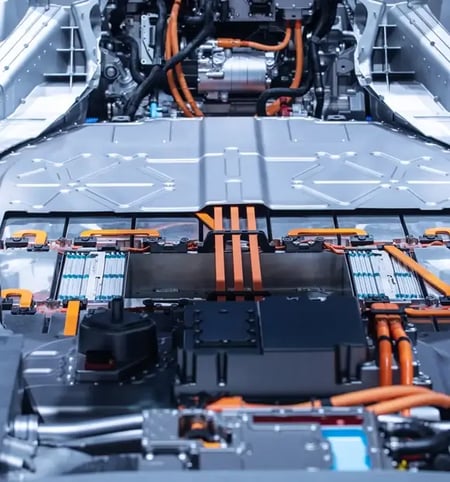

Critical seal areas on EV sub-assemblies

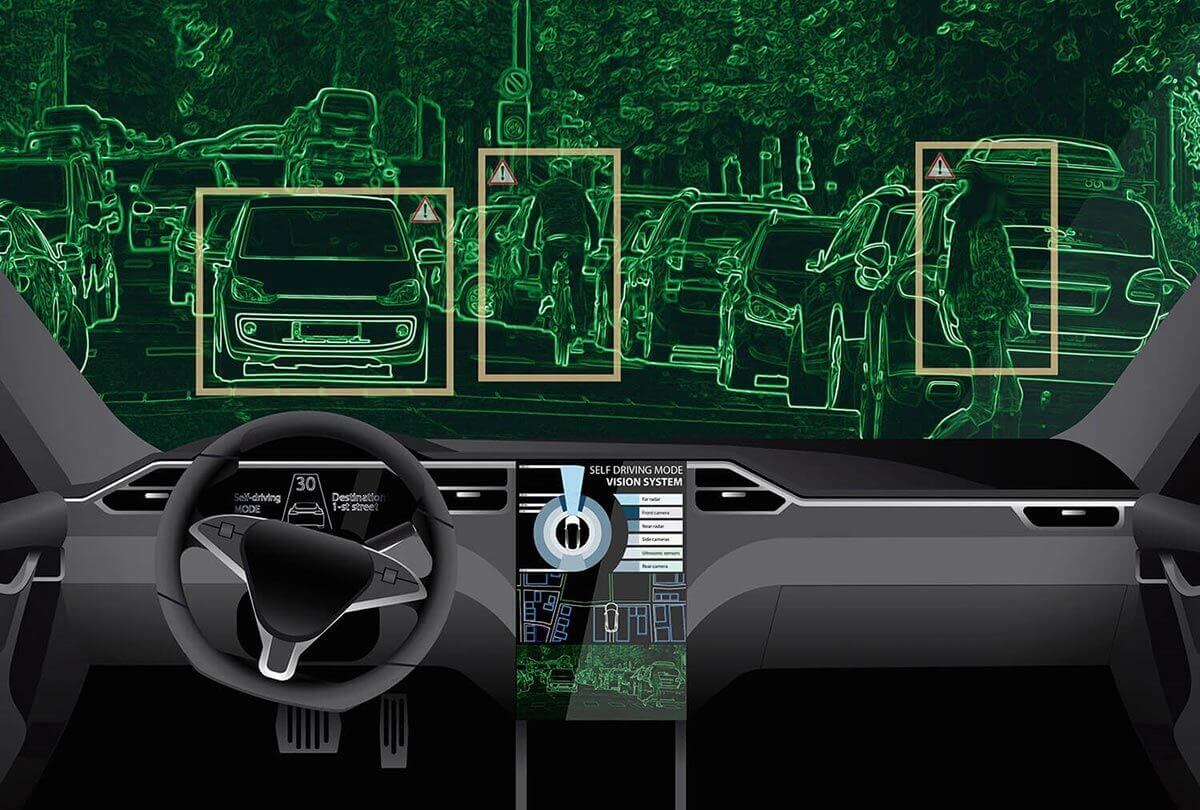

Critical seal applications in the electric mobility sector include: absolute moisture exclusion in power inverter units, charge port coupling, output shaft seal efficiency improvements, coolant pumps and manifolds, Hydraulic braking, vehicle ride control and suspension, and low closure force battery enclosure seals. We’ll keep pace as you iterate with fast prototyping, and support design recommendations with comparative data developed from our Test Bench capability.