Securing your seal supply chain obviously requires robust processes and strong global relationships. But most importantly it takes people who care, coming in every day and getting it done.

Where & when you need it from Darcoid on Vimeo.

Pack, Print, Sterilize

We’ll ship however you need it: from bulk packaged to color coded and single bagged. Typical services include:

Operational Services

We provide a broad selection of secondary processes to save you time and improve your operational efficiencies:

Product Services

Secondary processes (in house or outsourced). Consult with our technical team for use applications.

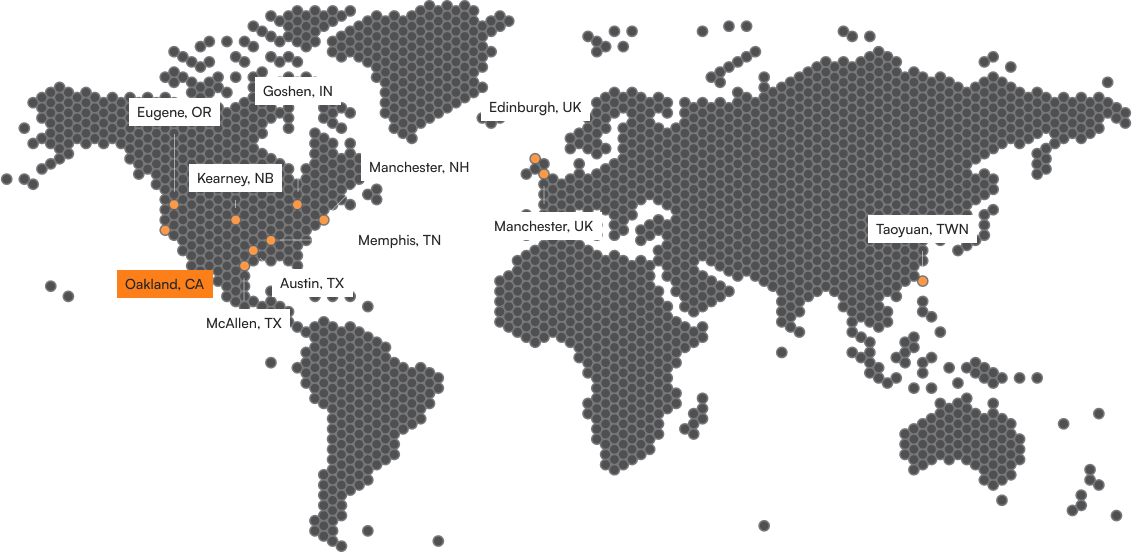

With inventory forward positioned in the USA, Europe and Asia we keep your lines running wherever in the world your product is assembled. Being easy to do business with is critical and everyone in our customer experience team is motivated and empowered to align with your business model to make that happen.

Our fulfillment and supply chain teams align with your materials planning and procurement team. You may design, manage quality, and manufacture under the same roof. You may have a purpose-built factory in a different state to build closer to your customer or to take advantage of lower labor costs in different continents. Wherever possible we forward position inventory close to where you need it.

Frequently Asked Questions

A person, team, or organization who strives to be first in their field. New products, ideas, approaches to create results that enable breakthrough performance, or entirely new functionality and capabilities. Do you want to make an impact on the world we live in? So do we.

Next Level® enables Darcoid to scale and keep pace ahead of your growth. Next Level® drives integration of our four business pillars with your similar or like business pillars. Our engineers talk to your engineers. Our Customer Success team works closely with your planning and sourcing teams. Our key Quality engineers develop working relationships with your SQE team. Our management team knows yours – so we learn how to focus efforts and resources to help drive your success.

Talk can be cheap. We back our Next Level® teams with data so we can measure success and improve goals as we integrate with your teams further. Our Next Level® teams share unique to you, our customer, scorecards – to give a roadmap of where we need to go. What further performance is available to achieve the maximum value from the relationship. We use this same methodology to drive integration with our manufacturing partners. Alignment up and down the supply chain. Next Level® is a super effective alignment model and yes, we trademarked it!

Absolutely. A seal is inexpensive unless it fails. So, we evaluate your requirements from a risk control perspective. We take the time to understand the impact a seal has on the functionality of your product. We make recommendations for alternate sources based on our long-established practices. It starts with understanding your logistics requirements, your quality expectations, and the in-process performance of the seal you’re looking for as a second source. Our supply chain team, quality department, and applications engineers work together to bring you the best possible, lowest risk, alternate source. Something you can rely on for the lifetime of your program.

The vast majority of seal failures are rooted in either inadequate original design and validation, or if something has changed in your application parameters, the mating hardware and fluids, or the seal itself. Changes in the seal can slip through if the seal is under specified, improperly stored and handled or if quality controls are not robust. The resultant failure modes can be thermal damage, incompatibility with fluid being sealed, insufficient squeeze, spiral failure, nibbling, extrusion, compression set, glass transition, explosive decompression, and so on.

Test Bench is a loose term but can be summed up as where we put theory into practice and develop empirical performance data. This means engineers and technicians tear down assemblies to look at the incumbent seal, install and evaluate alternative designs, then develop objective data and observations to compare results. Our team designs test fixturing and data acquisition techniques. We can actuate assemblies in temperature-controlled environments from -68 to180C. We can run soak studies on samples and perform compression set testing in YOUR fluids and temperatures. The result? Faster path to success for your project, supported by empirical performance data. Replacing guestimates with certainty.

Size matters. The chances are you don’t have a seven-figure seal spend concentrated on a single line item. Seal manufacturing plants like running at maximum efficiency. Unless you have that concentrated big spend, or have a line that warrants an exclusive 24x7 production cell then you’ll have no leverage in the relationship. Darcoid has that spend, we have that leverage, we have the Next Level® relationships which get you the results you need. We’re small enough to care, big enough to deliver. Darcoid is that powerful advocate you need to assure your lines keep running with quality you can count on. That’s why our customers chose to work with us – to get the best seal, zero defect, whenever and wherever you need it.

A global Biopharma leader needed to replace a legacy seal no longer supported by the OEM. They had no prints or specifications to guide their resolution path.

A brand leader in high performance ride control components was having problems scaling a shuttle valve into a smaller package size. Actuation and performance of the valve component was inconsistent..

Darcoid FKM (Fluorocarbon) Material Compound Data Sheet #4006. Original test data stored in the Darcoid Compound Database. This material is available to run in our manufacturing partner plant in N..

Darcoid FKM (Fluorocarbon) Material Compound Data Sheet #4048. Original test data stored in the Darcoid Compound Database. This material is available to run in our manufacturing partner plant in N..